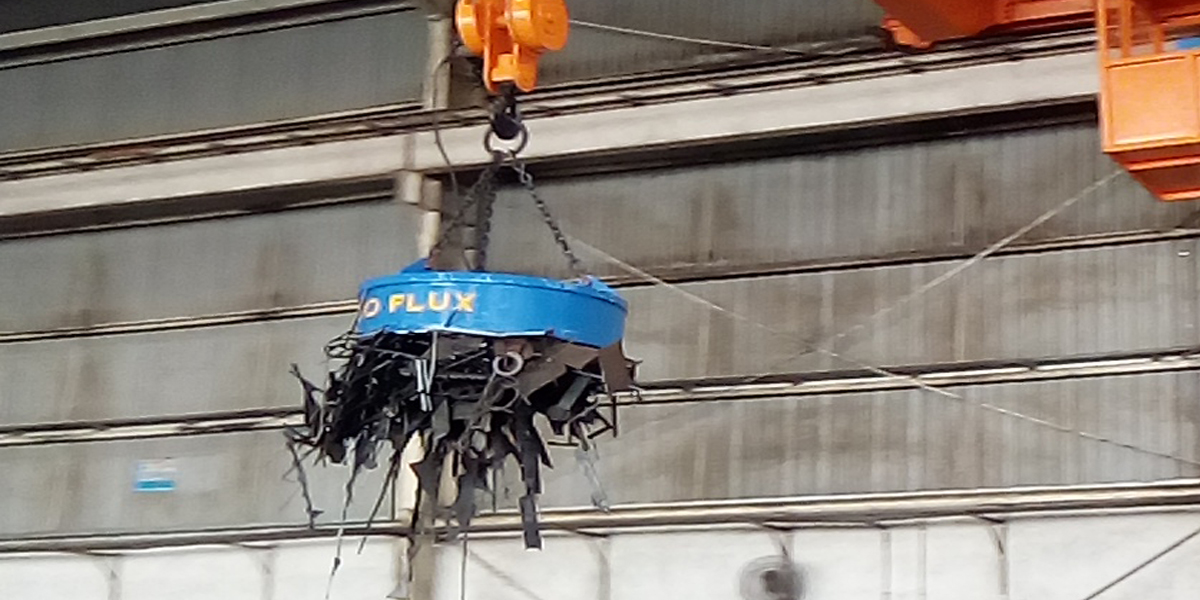

Circular Lifting Electro Magnet

We are a trusted circular lifting electromagnet manufacturer and supplier. We specialize in industrial lifting Electromagnets and Circular Lifting Magnets.

Use

We offer a wide range of products, including circular lifting magnets and lifting magnets specifically designed for steel and scrap materials for industries like foundries, steel plants, material handling.

Our magnets are perfect for transporting steel in metalworking plants, whether it’s steel parts, forgings, castings, plates, or even booms, channels, angles, rods, and bars. With our reliable lifting supports and mechanical devices, you can ensure safe and efficient lifting operations in your facility. Trust us for all your hoisting magnet needs and experience seamless steel handling like never before.

Electromagnet Body

Our Electromagnets with the casting grade of IS4491- 1994. Also, we produce high permeability mild steel coasting and fabricated body with heavy ribs which gives the mechanical strength and increased radiation surface.

Magnetizing Coils

Aluminum or copper coil with DFGC Double Fiberglass insulation of class H standard.

Bumper Plates

High graded Manganese Steel Casting as per IS-276:2000 or Stainless steel plate provided at the bottom where circular magnet with heavy ribs are added for more strength. These are clamped in position by the center and outer poles, offering complete protection to the coil from heat, impact or shock during operation.

Features

- Rugged all-welded construction for enhanced durability and longevity.

- Effective moisture-proofing to withstand challenging environments.

- Powerful attraction force for efficient lifting operations.

- Specially designed energizing coils to optimize electrical and mechanical properties.

- Low energy consumption for cost-effective operations.

- Heat-resistant insulating material with a long service life.

- Simple and convenient installation, operation, and maintenance for ease of use.

- hjhghj

MAGNET DIA. - 650 mm

| MODEL NAME | EF CLM 1 |

| KW | 2.5 |

| APPROXIMATE WEIGHT (TON) | 0.6 |

LIFTING CAPACITY (KGS) |

|

| HEAVY MELTING SCRAP | 200 |

| PIG IRON | 250 |

| STEEL TURNING | 100 |

| SINGLE SOLID | 3500 |

MAGNET DIA. - 850 mm

| MODEL NAME | EF CLM 2 |

| KW | 3.5 |

| APPROXIMATE WEIGHT (TON) | 0.7 |

LIFTING CAPACITY (KGS) |

|

| HEAVY MELTING SCRAP | 350 |

| PIG IRON | 400 |

| STEEL TURNING | 150 |

| SINGLE SOLID | 6000 |

MAGNET DIA. - 950 mm

| MODEL NAME | EF CLM 3 |

| KW | 4.5 |

| APPROXIMATE WEIGHT (TON) | 0.8 |

LIFTING CAPACITY (KGS) |

|

| HEAVY MELTING SCRAP | 400 |

| PIG IRON | 500 |

| STEEL TURNING | 180 |

| SINGLE SOLID | 7000 |

MAGNET DIA. - 1100 mm

| MODEL NAME | EF CLM 4 |

| KW | 6 |

| APPROXIMATE WEIGHT (TON) | 1.0 |

LIFTING CAPACITY (KGS) |

|

| HEAVY MELTING SCRAP | 500 |

| PIG IRON | 620 |

| STEEL TURNING | 210 |

| SINGLE SOLID | 8000 |

MAGNET DIA. - 1250 mm

| MODEL NAME | EF CLM 5 |

| KW | 8 |

| APPROXIMATE WEIGHT (TON) | 1.5 |

LIFTING CAPACITY (KGS) |

|

| HEAVY MELTING SCRAP | 720 |

| PIG IRON | 900 |

| STEEL TURNING | 300 |

| SINGLE SOLID | 12000 |

MAGNET DIA. - 1350 mm

| MODEL NAME | EF CLM 6 |

| KW | 12 |

| APPROXIMATE WEIGHT (TON) | 2.3 |

LIFTING CAPACITY (KGS) |

|

| HEAVY MELTING SCRAP | 1000 |

| PIG IRON | 1200 |

| STEEL TURNING | 400 |

| SINGLE SOLID | 15000 |

MAGNET DIA. - 1600 mm

| MODEL NAME | EF CLM 7 |

| KW | 15 |

| APPROXIMATE WEIGHT (TON) | 3.5 |

LIFTING CAPACITY (KGS) |

|

| HEAVY MELTING SCRAP | 1400 |

| PIG IRON | 1600 |

| STEEL TURNING | 500 |

| SINGLE SOLID | 18000 |

MAGNET DIA. - 1800 mm

| MODEL NAME | EF CLM 8 |

| KW | 18 |

| APPROXIMATE WEIGHT (TON) | 4.8 |

LIFTING CAPACITY (KGS) |

|

| HEAVY MELTING SCRAP | 1800 |

| PIG IRON | 2300 |

| STEEL TURNING | 800 |

| SINGLE SOLID | 22000 |

MAGNET DIA. - 2000 mm

| MODEL NAME | EF CLM 9 |

| KW | 24 |

| APPROXIMATE WEIGHT (TON) | 5.6 |

LIFTING CAPACITY (KGS) |

|

| HEAVY MELTING SCRAP | 2600 |

| PIG IRON | 3000 |

| STEEL TURNING | 1250 |

| SINGLE SOLID | 50000 |

MAGNET DIA. - 2500 mm

| MODEL NAME | EF CLM 10 |

| KW | 27 |

| APPROXIMATE WEIGHT (TON) | 6.5 |

LIFTING CAPACITY (KGS) |

|

| HEAVY MELTING SCRAP | 3200 |

| PIG IRON | 3600 |

| STEEL TURNING | 1500 |

| SINGLE SOLID | 62000 |

Watch Demo

Build Unstoppable Power with Our Electromagnetic Lifting Solutions

Check out our wide range of magnetic solutions to find the best fit. Our Team of specialists are here to assist you.